FIND YOUR WEREHOUSE & LOGISTICS SOLUTIONS

FIND YOUR WEREHOUSE & LOGISTICS SOLUTIONS

Carton Clamps are designed for palletless load handling and are recommended in locations where large amounts of products are packed in carton boxes. The Bolzoni Auramo carton clamps are extensively used for the handling of “white goods”, in both factories,warehouses and forwarding companies such as washing machines, refrigerators, microwave ovens, televisions and for the handling of other types of materials packed in cardboard boxes.

Thanks to the palletless handling, the carton clamp allows the optimization of warehouse storage space and reduction of the costs for packaging materials. Home appliance and carton clamps can have several pad versions, to fit different handling application, such as single oscillating pads on both arms, both arms rigid. Available also as 360° rotating version.

Dedicated clamps to fit single application needs

KS-C: Single or double oscillating pad

Version with Single or double oscillating arms for big load configurations (until 30 washing machines at the same time).

KS-C with Force Balance: Single oscillating pad

Version with FORCE BALANCE single oscillation granting perfect clamping force equalization for very high level of handling differentiation.

KS-CF: Both arms rigid/ No oscillation

Version with rigid arms for single and/ or limited picking (small number of units) configurations, this type of clamp is used very often also in the isolating material and styrofoam handling industry.

3-24: Front tilting version

Version with tilting arms to fully exploit the container height, typical of the refrigerators industry.

The most advanced technology in laser sensors for damage prevention and clamping force control

In the white goods industry the handling problems caused by the use of incorrect clamping force can create serious risks of products damaging: insufficient pressure results in the product being dropped, while too much pressure can crush or damage the package and its content.

Bolzoni Auramo integrates standard technical features of the KS-C model carton clamp with the most advanced technology in hydraulics, electronics and laser sensors for clamping force controlling.

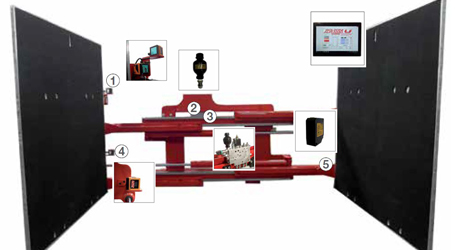

Clamping force control with Easy-MOVE Laser Sensors System

This new intelligent system is an electronic control of the clamping force, driven by the number and dimensions of the unit loads which have to be handled. The laser sensors and the electronic micro-control allow the system to detect the load and input the correct clamping pressure through a proportional pressure relief valve.

The micro-control can be managed by a Bolzoni Auramo configuration tablet. Through an easy procedure (touchscreen based) the operator can adjust the handling load parameters, recalibrate the sensors if necessary, associate the opening ranges to the required pressure levels. It is also possible to recalibrate the pressure levels in case of introduction of new loading schemes and finally to switch to single pressure manual mode.

Bolzoni Auramo Easy-move system is providing outstanding benefits to all the operators of the logistic chain in white goods (end users, 3PLs, forklift truck providers):